Table of Content

▼According to NITI Aayog, 80% of two- and three-wheelers, 40% of buses, and 30% to 70% of cars in India will be electric vehicles by 2030. “Between 2019-20 and 2020-21, the proportion of two-wheelers has increased by 422%, three-wheelers by 75%, four-wheelers by 230%, and electric buses by 1,200%.” Nitin Gadkari, Minister of Road Transport and Highways, said

We must stop and consider whether this breakneck speed of introduction of electric vehicles will lead to net zero emissions, which is our ultimate goal for sustainable development.

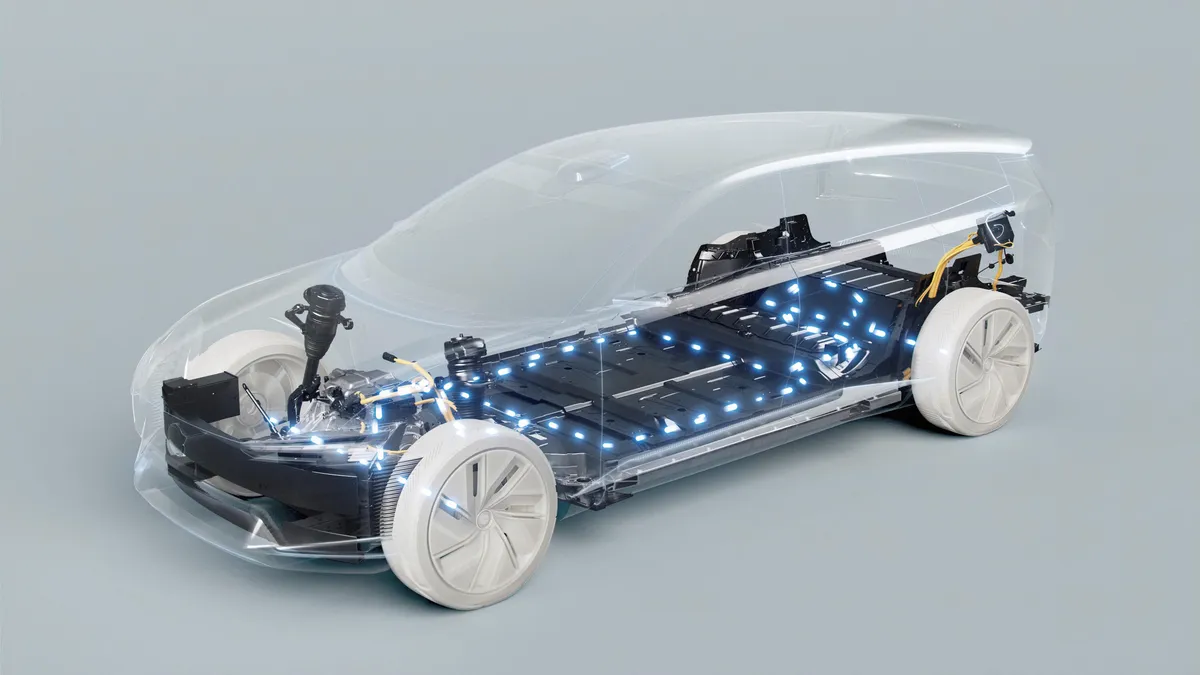

Road transport is one of the sectors with the highest greenhouse gas emissions and therefore needs a deep look. Countries around the world have planned to convert road transportation to electric vehicles. The heaviest and most expensive component of an electric car is its battery. An electric vehicle battery (EVB) or traction battery powers the electric motors of battery electric vehicles (BEV) or hybrid electric vehicles.

Unlike starter, lighting, and ignition (SLI) batteries, electric vehicle batteries are lithium-ion and designed to provide a high power-to-weight ratio and energy density. Because they reduce vehicle weight and improve performance, smaller and lighter batteries are preferred.

Many current battery technologies have a lower specific energy than liquid fuels, limiting the range of fully electric vehicles. Lead-acid, nickel-cadmium, nickel-metal hydride, and lithium-ion batteries have been used in electric vehicles; These are rechargeable batteries. Unlike nickel-cadmium batteries, lithium-ion batteries currently in use can be drained and recharged daily at any charge level.

The battery, which makes up a significant portion of the cost and weight of an electric vehicle, has a negative environmental impact throughout the supply chain. The growth of the industry has led to a focus on creating ethical battery supply chains, especially as the supply of lithium poses numerous challenges as well as being a critical geopolitical issue.

Battery recycling

Battery recycling involves reusing and reprocessing batteries, to reduce their disposal as waste materials. Because batteries contain harmful chemicals and heavy metals, their improper disposal poses environmental risks, raising concerns about water and soil contamination. Therefore, proper recycling of batteries is essential to align their use with environmental and health requirements.

As electric mobility continues to increase globally, there is a growing demand for electric vehicle (EV) batteries. This increase in demand has spurred a significant expansion in battery production, with capacity expected to exceed five terawatt-hours (TWh) annually. This requires the construction of giant factories around the world by 2030. In addition, there is a noticeable increase in the volume of electric vehicle batteries reaching the end of their useful life, with expectations indicating that more than 100 million vehicle batteries will be retired in the future. If it is not completely recycled, it becomes an environmental hazard.

The transition from fossil fuel-based mobility to electric mobility brings environmental benefits and cost savings to consumers, but the transformation of our transportation system requires the design and expansion of new supply chains. This dilemma represents an opportunity to create a green supply chain that is more stable, robust, efficient, and sustainable than the fossil fuel and internal combustion vehicle sectors, but disposal of end-of-life batteries will remain a problem.

Despite the significant shift to electric vehicles in China, Europe, and the United States, most battery materials suitable for recycling still come from consumer electronics cells, such as those found in laptops and other household items, and from manufacturing waste from defective battery cells that do not pass quality control.

Installing a new battery can generate up to 30% of waste during cell manufacturing, causing a major recycling and disposal problem. Currently, end-of-life EV batteries are more common in China, where EV adoption has become widespread. Worldwide, waste cell production will remain the dominant source of battery recycling materials until 2030. After that, end-of-life EV battery volumes will exceed waste cell production.

Lithium and nickel mining

Electric vehicle (EV) battery chemistry varies between models and suppliers. However, a basic lithium-ion pack typically requires critical heavy metals. Primarily, lithium is a key component; However, many packages also include varying amounts of cobalt and nickel.

It is important to note that these minerals are not available in their pure form. Cobalt and lithium do not occur naturally in their pure form, and nickel is only found in small amounts outside the mineral. Here the extraction and refining process becomes necessary, which leads to associated economic and environmental costs.

Companies obtain cobalt as a byproduct of nickel mining, and extracting the metal from the ore usually involves one of two methods: hydrometallurgy or pyrolysis of the metal. The choice of extraction process depends on the specific compound and the concentration of the metal as well as the level of environmental damage.

Hydrological mineral extraction uses an aqueous solution to extract the desired materials, while thermal mineral extraction methods rely on heat to separate required components from unwanted components.

Before the 1990s, lithium mining primarily involved extracting it in solid form from a few minerals. In modern times, most lithium comes from brines found beneath layers of salt. The extraction process involves drilling the brine, pumping it to the surface, and leaving it in evaporation ponds for several months or years until it reaches the desired lithium concentration.

The liquid is then transported to a processing facility, where it undergoes filtration and chemical treatment to produce the final product, typically lithium carbonate in the context of an electric vehicle (EV) battery.

From an environmental perspective, mining requires extensive land, water, and energy resources. Chemicals used in metal processing must be sourced, and proper disposal of unwanted materials can generate hazardous waste. In addition, mining activities can cause harmful environmental impacts, such as soil and water pollution, air pollution, soil erosion, and landslides.

Keeping all this in mind, shouldn't we reconsider the policy of transition of road vehicles despite India's discovery of lithium deposits?

Also Read: Suzuki aims for sky, to make e-air copters

Mehul Jain

EV Specialist & Clean Mobility Advocate. Mehul Jain is an expert in India’s evolving electric vehicle ecosystem, with a focus on EVs, charging infrastructure, and sustainable mobility. His articles cover everything from government subsidies to range insights, helping readers navigate the shift to cleaner transportation.

_1770886465.webp)

_1716799620.webp)